Welcome to OREMA's exclusive range of Front Terminal Batteries – the ideal choice for those who prioritize efficiency, space-saving design, and unwavering reliability in their power needs. Front Terminal Batteries,front terminal sla battery,front terminal storage battery,front terminal agm battery,12V front terminal batteries OREMA POWER CO., LTD. , https://www.oremapower.com

Innovative Design for Effortless Installation and Service

Our OREMA UNF series front terminal batteries redefine convenience with their integrated handles and accessible front terminal connections. Designed for seamless integration into both 19-inch and 23-inch battery cabinets, these batteries promise hassle-free installation and maintenance – a perfect fit for industrial, utility, and telecommunication settings.

Advanced AGM Technology: Power, Performance, and Peace of Mind

At the heart of our OREMA UNF series lies the AGM (Absorbent Glass Mat) technology. This innovation encapsulates the electrolyte in glass fiber mats, offering enhanced performance and maintenance-free operation. Known for their high reliability and longevity, these batteries are the go-to solution for critical backup power requirements.

Features of OREMA Front Terminal Storage Battery

Easy Installation & Space Efficiency: With front access terminals, our batteries simplify installation and servicing, saving you time and space.

High Energy Density: Our batteries deliver superior performance while occupying less space, enhancing energy density.

Exceptional Discharging Ability: Thanks to radial grid design and tight assembly technology, these batteries excel in high-rate discharge performance.

Longer Float Service Life: Enjoy over 8 years of reliable service at 25°C, backed by unique corrosion-resistant grid alloy.

Maintenance-Free Operation: Our AGM technology ensures efficient gas recombination and eliminates the need for electrolyte maintenance.

Low Self Discharge: High purity raw materials reduce self-discharge, ensuring longevity.

Environmental & Nonpolluting: Our batteries feature Gas Recombination technology, preventing acid fog emissions.

Safe & Reliable: An efficient venting system releases excess gas and reseals valves, safeguarding against bursting.

Versatile Applications of OREMA Front Terminal AGM Battery

Our Front Terminal Batteries are designed for diverse applications including:

19inch/23inch standard power supply cabinets

Communication Systems (Switches, Microwave Stations, Mobile Base Stations, Data Centers, Radio/Broadcasting Stations)

Special or LAN Power Supply Systems

Signal, Emergency Lighting, EPS & UPS Systems

Broadband, Electric Utility, Telecom, Central Office, Fire Alarms, and Security Systems

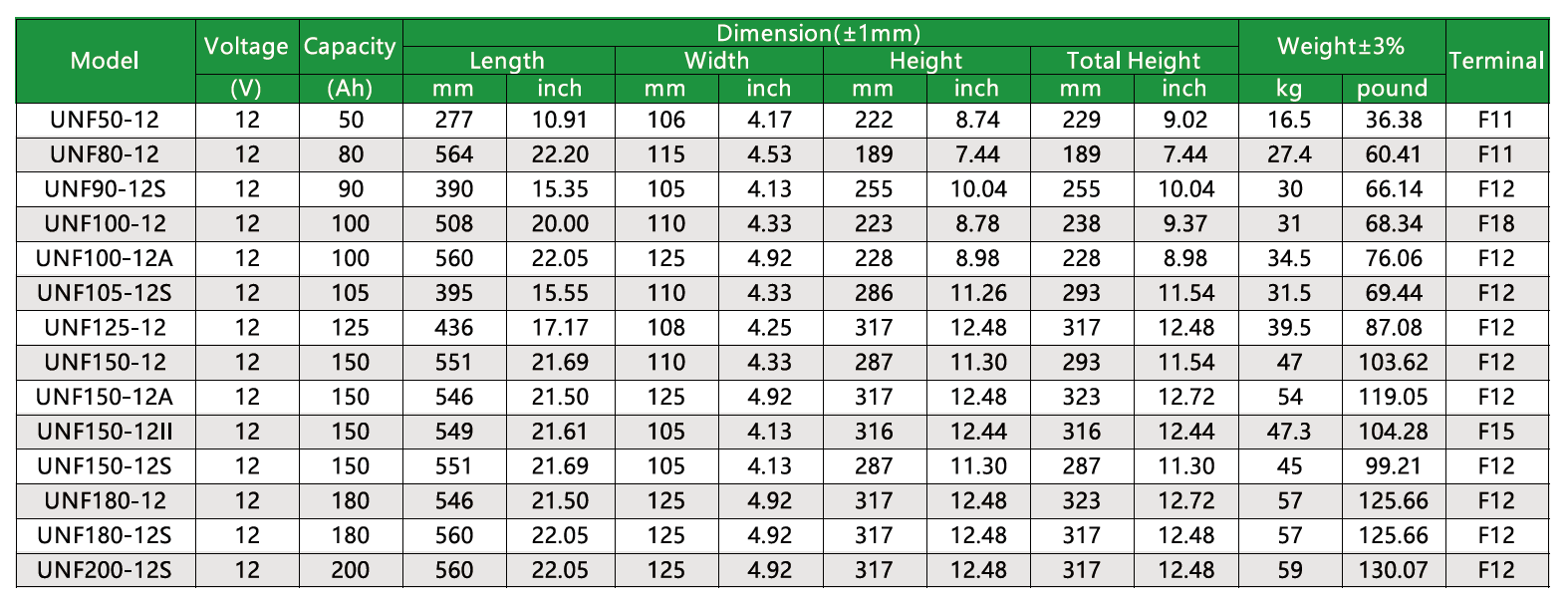

Specifications of the OREMA UNF series 12V Front Terminal Batteries:

Tailored Solutions with OREMA's Expertise

With 20 years of innovation in sealed lead-acid battery manufacturing, OREMA stands as a rising star in the industry. Our commitment to quality is unwavering, as evidenced by our comprehensive quality management system. Embracing unity, growth, trust, and quality-first ethos, our team is dedicated to providing top-tier power solutions and personalized services. Meeting and exceeding customer expectations remains our perpetual goal.

Pull-up resistors are essential components in digital circuit design, serving multiple functions depending on the application. When a TTL circuit drives a CMOS circuit, and the TTL output high level is below the minimum required for the CMOS input (typically 3.5V), a pull-up resistor must be added at the TTL output to ensure the signal reaches the proper high voltage level. Similarly, open-collector (OC) gates require pull-up resistors to function correctly, as they cannot drive a high level on their own.

In microcontroller designs, pull-up resistors are often used on output pins to enhance drive capability. On CMOS chips, unused pins should not be left floating due to the risk of static damage. Pull-up resistors help prevent this by providing a defined logic level, reducing input impedance, and offering a discharge path. Additionally, pull-up resistors can improve noise margin by ensuring stable input levels, which enhances the circuit's immunity to interference.

For bus systems, pull-up resistors also play a role in reducing electromagnetic interference. When pins are left unconnected, they can act as antennas, picking up unwanted signals. In long-line transmission, resistance mismatch can cause signal reflections, and pull-up or pull-down resistors help match impedances, minimizing such issues.

When selecting the value of a pull-up resistor, several factors must be considered. The resistor must be large enough to minimize power consumption but small enough to provide sufficient current for driving the next stage. For high-speed circuits, larger resistors may slow down signal transitions, so values between 1kΩ and 10kΩ are commonly used. The choice also depends on the characteristics of the switching device and the input requirements of the downstream circuit.

The balance between drive strength and power consumption is crucial. A smaller resistor provides stronger drive but consumes more power, while a larger resistor reduces power use but may weaken the signal. The threshold levels of the circuit also affect the selection—ensuring that the output remains within the valid high or low range is critical. Additionally, frequency response must be considered, as larger resistors can introduce RC delays, affecting signal integrity.

The principle for pull-down resistors is similar, though the direction of current flow differs. In an OC gate, when the output is high, it enters a high-impedance state, and the pull-up resistor supplies the necessary current. Input ports typically draw less than 100μA, while output ports can source around 500μA. At 5V, the high and low thresholds are generally 2V and 0.8V, respectively.

For example, if the output current is 500μA, a 8.4kΩ pull-up resistor would pull the output below 0.8V, which is the minimum acceptable low level. If higher current is needed, the resistor value can be reduced. Conversely, when the output is high, the leakage current of the transistor is negligible, and the pull-up resistor must supply enough current to meet the input requirements of the next stage.

In CMOS circuits, especially with the 74HC series, leakage current becomes significant, and the actual current drawn by the I/O port varies with the voltage level. While these are general guidelines, the key idea is that when the output is high, the input must be properly biased, and when it’s low, the output should not be driven to avoid excessive current flow into the input.

Unused input pins in digital circuits must be connected to a fixed level, either through a 1kΩ resistor to VCC or ground. This prevents floating states, reduces external interference, protects internal ESD diodes, and ensures reliable operation. Pull-up and pull-down resistors are also used to limit current, adjust signal levels, and stabilize the circuit.

In some cases, pull-up resistors are used to provide a default state, such as in motor control circuits where the upper and lower transistors in an H-bridge must not be simultaneously active. Proper initialization with pull-up or pull-down resistors helps prevent shorting.

In summary, pull-up resistors serve as current-limiting devices that help maintain signal integrity, improve noise immunity, and ensure stable logic levels. Their selection depends on the specific needs of the circuit, including speed, power, and drive capability. Whether used in simple button interfaces or complex bus systems, pull-up resistors are a fundamental tool in digital design.