Pull-up resistors are essential components in digital circuit design, serving multiple critical functions. When a TTL circuit drives a CMOS circuit, and the high-level output of the TTL is below the minimum required for the CMOS (typically 3.5V), a pull-up resistor should be added at the TTL output to ensure the signal reaches the necessary high level. Similarly, open-collector (OC) gates require a pull-up resistor to function properly, as they cannot drive a high level on their own.

In microcontroller applications, pull-up resistors are often used to enhance the driving capability of output pins, especially when interfacing with external devices that require more current than the microcontroller can provide. On CMOS chips, unused input pins must not be left floating, as this can lead to static damage. A pull-up resistor helps by reducing input impedance and providing a discharge path, ensuring stable operation.

Additionally, pull-up resistors help improve the noise margin of input signals by maintaining a clear high or low state, which enhances the circuit’s immunity to interference. For buses, pull-up resistors prevent signal distortion caused by electromagnetic interference, especially when pins are left unconnected. In long-line transmission systems, resistance matching using pull-up or pull-down resistors can reduce signal reflections, improving signal integrity.

When selecting the value of a pull-up resistor, several factors must be considered. It needs to be large enough to minimize power consumption and current draw, but also small enough to provide sufficient driving current. For high-speed circuits, excessively large pull-up resistors can slow down signal transitions, so a balance is needed—common values range between 1kΩ and 10kΩ. The same principles apply to pull-down resistors.

Key considerations include the trade-off between drive capability and power consumption, the requirements of the lower-level circuit, and the threshold levels of the logic gates involved. Additionally, frequency characteristics play a role, as larger resistors can introduce RC delays due to capacitance in the circuit. Proper resistor selection ensures reliable signal transitions and proper voltage levels across the entire system.

The principle for setting pull-down resistors is similar to pull-up resistors. For example, in an OC gate, when the output is high, it enters a high-impedance state, and the pull-up resistor provides the necessary current. The input current per port is typically limited to around 100μA, while the output current is about 500μA at 5V. The high and low thresholds are usually 2V and 0.8V, respectively.

When choosing a pull-up resistor, the minimum value is determined by ensuring the output voltage drops below 0.8V when pulled down. If the output current increases, the resistance can be reduced to maintain the low level. Conversely, when the output is high, the leakage current of the transistor is ignored, and the resistor must be chosen to ensure the input receives sufficient current.

For CMOS devices like the 74HC series, leakage current becomes significant, and the actual current drawn from the IO port varies depending on the logic level. While these are general guidelines, the key takeaway is that when the output is high, the input must be driven, and when low, it should not be over-driven to avoid unreliable behavior.

Unused input pins in digital circuits should always be connected to a fixed level—either through a 1kΩ resistor to VCC or ground. This prevents floating inputs, reduces noise sensitivity, protects internal ESD diodes, and limits current flow. Pull-up and pull-down resistors are also used to change signal levels, stabilize floating states, and increase output drive strength when necessary.

In interface circuits, pull-up resistors are commonly used to ensure correct logic levels and prevent accidental shorting, especially in motor control or inverter bridge applications where both upper and lower transistors must not be active at the same time. A pull-up resistor ensures the default state is known, preventing unintended operation during startup or failure conditions.

In summary, pull-up resistors serve to define signal levels, protect circuits, improve noise immunity, and ensure reliable communication between different logic families. Their selection depends on the specific application, power constraints, and signal speed requirements.

OREMA's commitment to innovative, efficient, and reliable battery solutions has established us as a global leader in the industry. OREMA General Purpose AGM Batteries, embodying this commitment, are designed with advanced valve-regulated lead-acid technology. These Vrla batteries are exported to over 80 countries, meeting the diverse needs of various sectors. - Rapid Recovery Post-Discharge: These batteries quickly recover their capacity after deep discharge, ensuring consistent performance. - Advanced Sealing Technology: Utilizing automated heat sealing and epoxy resin automatic filling, coupled with TTP welding technology, the UN series guarantees no electrolyte leakage, ensuring reliability and maintenance-free operation. - Wide Operating Temperature Range: Ideal for outdoor use in various environments, these batteries are characterized by uniformity and low internal resistance. 2. Versatility: Ideal for both standby and energy storage applications. 3. Durable Plate Design: Enhanced plate construction for a long service life. 4. Innovative Lead-Calcium Alloy Formula: Increases corrosion resistance. 5. Specialized Separators: Boost internal performance. 6. High Thermal Capacity: Reduces the risk of thermal runaway. 7. Efficient Gas Recombination: High efficiency in gas recombination. 8. Minimal Water Loss: Virtually eliminates electrolyte stratification. 9. Extended Shelf Life: Longer storage periods without performance compromise. 10. Exceptional Deep Discharge Recovery: Rapid capacity recovery after deep discharges. As a global leader in battery technology, OREMA and its OREMA AGM batteries offer more than just power; they represent a synergy of innovation and reliability. We invite battery purchasers and distributors to explore our cutting-edge products. Trust OREMA to empower your world with reliable and innovative energy solutions. General Purpose AGM Batteries,VRLA Batteries,AGM Batteries,General Purpose Battery,SLA Batteries,VRLA Battery,SLA Battery OREMA POWER CO., LTD. , https://www.oremapower.com

The OREMA UN series AGM batteries are a product of meticulous engineering, designed to cater to a broad spectrum of applications. With a wide range of capacities and models, these Sla batteries are equipped with AGM technology, ensuring sealed safety, low internal resistance, and high-sealed reaction efficiency. They are particularly suitable for use in communication systems, power systems, uninterrupted power supplies (UPS), solar energy systems, and alarm, fire, and security systems.

OREMA UN Series General Purpose AGM Batteries: A Blend of Technology and Versatility

- Deep Cycle Performance: The UN series batteries excel in small current deep cycle discharge, boasting a long cycle life and strong overcharge resistance at high temperatures.

Key Features of OREMA General Purpose Battery:

1. Extended Discharge Performance: Superior discharge characteristics over extended periods.

Application Scenarios for General Purpose AGM Batteries:

- Automotive and Electronics: Ideal for vehicles laden with electronics, marine, and RV applications.

- Backup Systems and Emergency Lighting: Suitable for UPS systems and emergency lighting.

- Industrial and Commercial Uses: Exceptional performance in industrial equipment and commercial devices.

Unique Advantages of AGM Technology:

- Maintenance-Free: Designed to prevent acid spillage, reducing water loss during usage.

- Charging Requirements: Special AGM chargers are required to maintain voltage below 14 volts.

- Optimized Electrolyte Utilization: Maximizes electrolyte surface area.

- Sealed Lead Acid Design: Known as Valve Regulated Lead Acid (VRLA), offering a leak-proof experience.

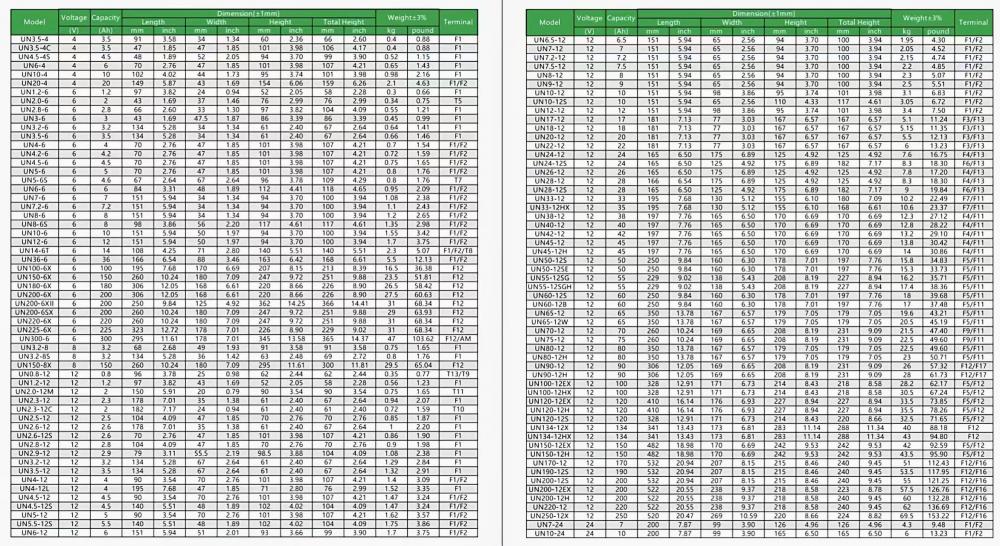

OREMA UN Series General Purpose Specification table of AGM Batteries